Request A quote

Our Services

Concrete Scanning /

Ground Penetrating Radar (GPR)

Since concrete is one of the most durable building materials, diamond tools need to be used to get through it. Our Concrete Cutting operators work in tandem with our scanning and locating technicians using their expertise to overcome potential obstacles through our “team-work” approach will significantly lower your often unforeseen inspection and concrete cutting costs.

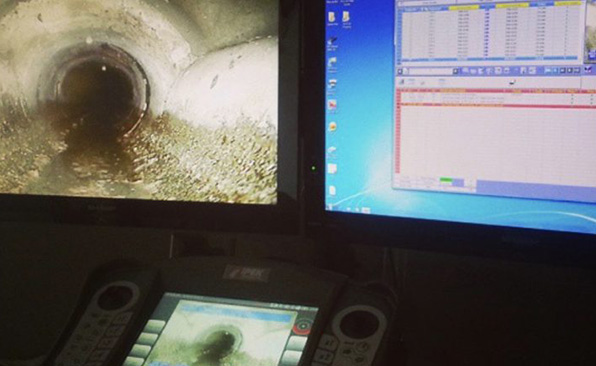

Ground Penetrating Radar

Video Inspection

Locating Services

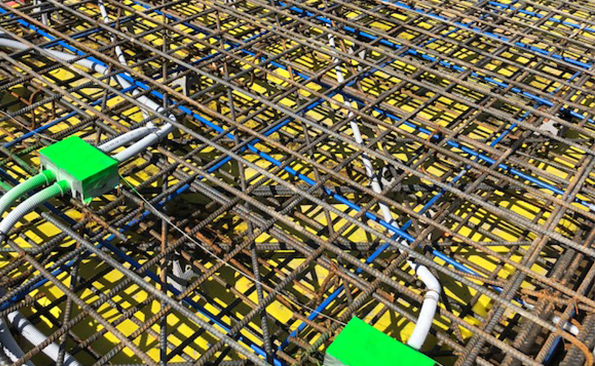

Beyond utility locating services, concrete scanning can provide comprehensive data on the condition of a structure, identifying potential weaknesses, and assessing structural integrity.

This information can be used to plan for maintenance, repairs, or upgrades, and can help to prevent costly and dangerous structural failures. Concrete scanning can also be used to locate and map rebar, post-tension cables, and other embedded features, which is essential for any project that involves cutting, drilling, or coring through concrete.

With advanced scanning technology, concrete scanning can provide a level of detail and precision that goes beyond what is possible with traditional utility locating services, making it an invaluable tool for construction, engineering, and infrastructure projects.

Safe2Core, a leading concrete scanning company, has received consistently positive customer reviews for their reliable and efficient services.

R.T.

Safe2Core is my “go to” scanning contractor. There are other available, but with Safe2Core I can trust the scan, they make my schedule and follow directives. I can point them to the work and they return with results.

Jessie Williams

Safe2Core has handled thousands of cores for us on our Parking Garage Solar PV projects, always doing their work respectfully, diligently and safely.

T.K.

Safe2Core, It was nice to work with you on the University of California Campus. Being able to call you with any issues we had and you being there to answer and resolve issues was really positive. The technicians you sent to the jobsite always conducted themselves in a professional and workmanlike manner and were easy to deal with while producing the outcome we anticipated. Thank you for your hard work and professionalism.

Risk Management

SAFETY: ALWAYS ON OUR RADAR

Safe2Core follows strict safety protocols and utilizes state-of-the-art equipment to ensure the safety of their employees and customers

BUDGET OVERRUNS

At Safe2Core, we understand the importance of staying within budget while providing reliable and accurate scanning services.

DAMAGED REPUTATION

We understand the importance of maintaining a strong reputation built on trust, reliability, and quality workmanship.

PROPERTY DAMAGE

We take every precaution to prevent damage to the property and surrounding areas during the scanning process.

INJURIES & ACCIDENTS

We understand the potential risks and hazards associated with concrete scanning, and we take every precaution to prevent injuries and accidents.